- Home

- Products

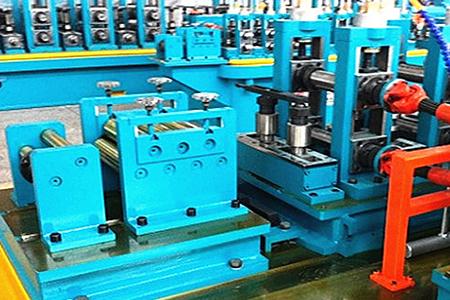

- ERW Tube Mill

- ERW Tube Mill, 8mm-32mm

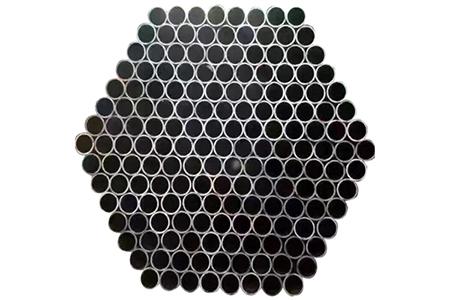

Round, Square, Rectangular Tube

ERW Tube Mill, 8mm-32mm

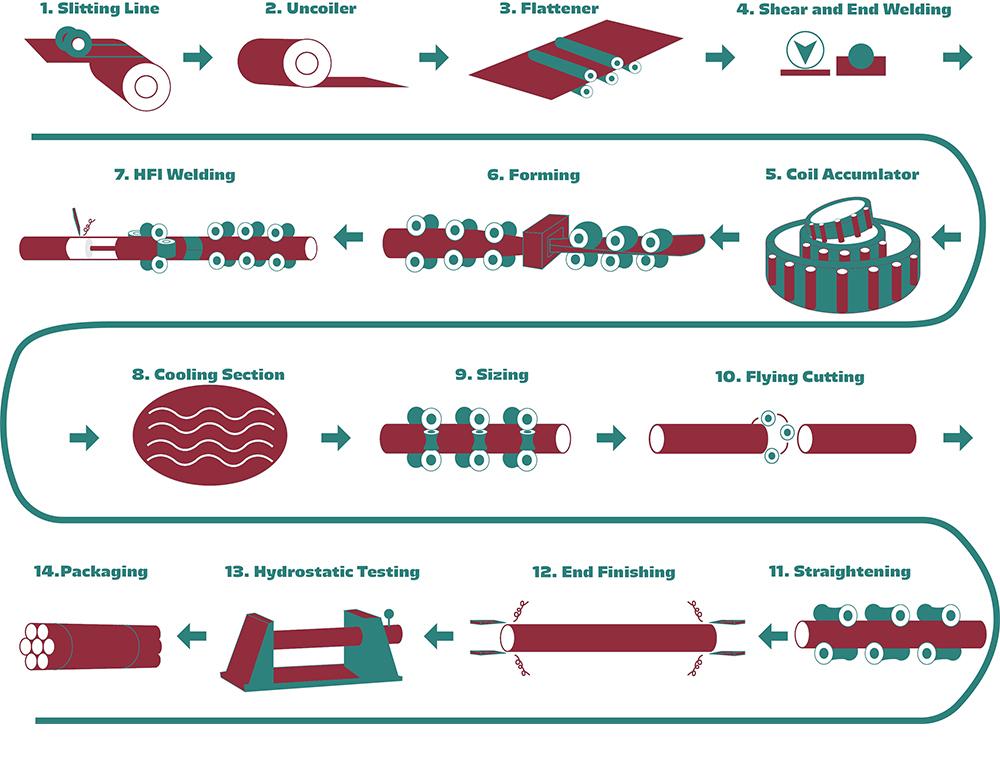

Production ProceduresSteel Coil → Double-arm Uncoiler → Shear and End Cutting & Welding → Coil Accumulator → Forming (Flattening Unit + Main Driving Unit + Forming Unit + Guide Unit + High Frequency Induction Welding Unit + Squeeze Roller) → Deburring → Water Cooling → Sizing & Straightening → Flying Saw Cutting → Pipe Conveyor → Packaging → Warehouse Storage

Basic Technical Parameters

Basic Technical Parameters | Production Capacity | |

| Round Pipe | 8mm - 32mm |

| Square & Rectangular Pipe | 8*8 - 25*25mm |

| Wall Thickness | 0.5 - 2.0mm (Round Pipe) 0.5 - 1.5mm(Square Pipe) |

| Speed | Max. 120m/min |

| Pipe Length | 3m – 12m |

| Steel Strip Specification | |

| Material | Low Carbon Steel, Q235, Q195 |

| Coil Inner Diameter | 460 – 510mm |

| Coil Outer Diameter | Max. 1500mm |

| Strip Width | 26mm – 100mm |

| Strip Thickness | 0.5mm – 2.0mm |

| Max. Coil Weight | 1500kgs |

| Electricity | |

| Dynamic Power | 380V, 3-phase, 50Hz (depends on local facilities) |

| Control Power | 220V, single-phase, 50 Hz |

| 4. Electric Installed Capacity: Approx.200kW | |

| Water Cooling | |

| Reservoir for High Frequency Equipment | 15 m³ |

| Reservoir for Circulating Cooling Water | 15 m³ |

| Compressed Air | |

| Pressure | 0.4MPa |

| Flow Rate | 0.5m³/hour |

| Line Speed: Max. 120m/min | |

| 8. Overall Production Line Dimension: 50m X 5m (L X W) | |

Each production line is carefully designed and produced according to customer requirements. We are devoted to providing customers with the best fit line.

Please send us your inquiry if you are seeking more information.

- No.8 Xingbei Street, Shiyan Road, Shijiazhuang, Hebei

- +86-311-888-33011

- ERW Tube Mills

-

Round, Square, Rectangular Tube

- (Direct Forming to Square) ERW Tube Mills

- Slitting Line

- Cut To Length Line

- Single Unit in Tube Mill

- TIG Tube Mills

- JCOE Pipe production line

Products

- CNC Workshop

- About Us

Quick Link