- Home

- Products

- Single Unit in Tube Mill

- Flying Cold Saw

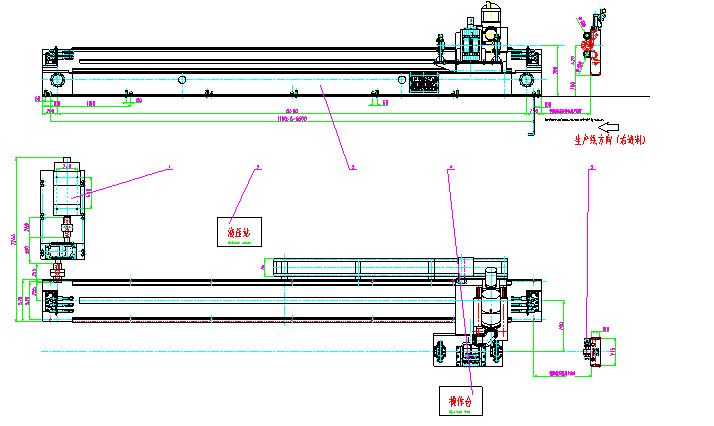

Flying Cold Saw

Our flying cold saw features a high accuracy of within ±1.0mm and disregarding processing objects made of either carbon steel or stainless steel. The finished pipe ends are smooth with no burrs. We offer the following two flying cold saw types:

| Flying Cut off | Orbital Flying Cut-off | ||

| Tube Diameter | 6 – 168 mm | Tube Diameter | 60 - 660 mm |

| Wall Thickness | 0.3 - 6 mm | Wall Thickness | 2.5 - 22 mm |

| Working speed | 60 - 120 m./min | Max Working speed | 30- 50 m./min |

Users can determine from the parameter table that using a regular flying cut off is better for pipe cutting in smaller diameters, and we highly recommend an orbital flying cut off for processing pipes with larger diameters.

- Fully automatic operation (Servo motor: Siemens/Yaskawa).

- LCD touchscreen.

- High speed and high precision cutting.

- Excellent cutting edge, no burrs.

Model List

Model List| Model | Pipe O.D. (mm) | Thickness (mm) | Max. speed (m/min) |

| Φ25 | Φ6-30 | 0.3-2.0 | 120 |

| Φ32 | Φ8-38 | 0.3-2.0 | 120 |

| Φ50 | Φ20-63.5 | 0.6-2.5 | 100 |

| Φ76 | Φ25-76 | 0.8-3.0 | 100 |

| Φ89 | Φ25-105 | 0.8-4.0 | 80 |

| Φ114 | Φ50-130 | 1.2-5.0 | 60 |

| Φ168 | Φ80-168 | 2.0-6.0 | 60 |

The orbital flying saw is mainly used for thick steel pipes with large diameters, and is applicable to different shapes and materials, such as round pipes, square pipes, profile pipes and more. Applicable materials include cold forming steel, Q235-345, J55, X42-80, N80 and more.

This orbital flying saw machine is automatically controlled (manual functions are available) and uses double milling cutter rotary cold cutting technology. The final cut is smooth and burr free, eliminating secondary deburring processes and saving money and labor.

Sophisticated mechanical equipment is equipped with an advanced Siemens control system to ensure the cutting accuracy and superior cutting effects, stable operation and low failure rate.

Features- Double-blades cutting

The double blades are controlled via an R-θ control mode, so that the blade cuts by the pipe contour. The price of two small blades is only half that of a single conventional blade. - TCT saw blades

This equipment uses TCT (tungsten carbide-tipped) saw blades with a higher strength and stiffness. It has a wider application range for cutting pipes with inner ribs and welded high strength pipes. TCT saw blades feature a service life that is twice that of normal blades - Inline cutoff, best quality with stable working performance and high efficiency.

We provide the best steel tube and pipe cutting solution for worldwide customers according to specific requirements for pipe diameter, wall thickness and line speed with a basic configuration for the servo motor and software.

Model List| Model | Pipe O.D. (mm) | Thickness (mm) | Length (m) | Length Tolerance (mm) | Cutting Speed (m/min) |

| CS-165 | ф60-ф165 | 2.5-7.0 | 5-12 | ≤±3 | Max.50 |

| CS-219 | ф89-ф219 | 3.5-7.0 | 6-12 | ≤±3 | Max.40 |

| CS-273 | ф114-ф273 | 4.0-10.0 | 6-12 | ≤±3 | Max.40 |

| CS-325 | ф165-ф325 | 5.0-12.7 | 6-12 | ≤±3 | Max.35 |

| CS-377 | ф165-ф377 | 5.0-12.7 | 6-15 | ≤±3 | Max.35 |

| CS-406 | ф165-ф406 | 5.0-14.0 | 6-15 | ≤±3 | Max.35 |

| CS-426 | ф165-ф426 | 5.0-16.0 | 6-15 | ≤±3 | Max.35 |

| CS-508 | ф165-ф508 | 5.0-16.0 | 6-18 | ≤±3 | Max.35 |

| CS-630 | ф219-ф630 | 6.0-16.0 | 6-18 | ≤±3 | Max.30 |

| CS-660 | ф219-ф660 | 8.0-22.0 | 6-18 | ≤±3 | Max.30 |

- No.8 Xingbei Street, Shiyan Road, Shijiazhuang, Hebei

- +86-311-888-33011

- ERW Tube Mills

-

Round, Square, Rectangular Tube

- (Direct Forming to Square) ERW Tube Mills

- Slitting Line

- Cut To Length Line

- Single Unit in Tube Mill

- TIG Tube Mills

- JCOE Pipe production line

- CNC Workshop

- About Us