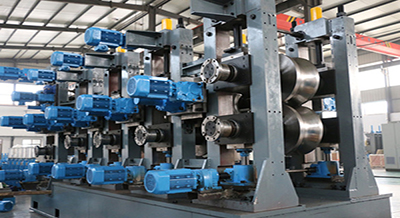

(Direct Forming to Square) ERW Tube Mills

-

- ERW Tube Mill, 120x120mm

Great flexibility and possibility for modifying tube dimensions without having to change the rollers during forming, welding, sizing and flattening for any sizes included within the equipment setting range.

Extreme reduction of equipment set up time.

-

- ERW Tube Mill, 150x150mm This tube mill directly forms square and rectangular tubes with a smaller inner arc radius, flatter brim, and overall better appearance compared to traditional methods for square forming from round tubes.

-

- ERW Tube Mill, 200x200mm The equipment is easy to adjust and requires no roller replacement for different specifications. The production line is automatically controlled, which significantly reduces the roller changing time, reduces labor, and improves production efficiency.

-

- ERW Tube Mill, 250x250mm It uses a multi-point bending method to reduce the forming steps, axial force, and side abrasion is bending step by step. It also saves power consumption and roller abrasion in order to ensure a higher product quality.

-

- ERW Tube Mill, 300x300mm It uses a combination roller which can produce square & rectangular tubes in a variety of different specifications. This significantly reduces the roller backup requirements and costs by almost 80%.

-

- ERW Tube Mill, 400x400mm This tube mill directly forms square and rectangular tubes with a smaller inner arc radius, flatter brim, and overall better appearance compared to traditional methods for square forming from round tubes.

-

- ERW Tube Mill, 500x500mm The square or rectangular shaping is formed before the welding process, with significant advantages in terms of saving both energy and material costs. The whole line features a low load, particularly in the sizing unit.

- No.8 Xingbei Street, Shiyan Road, Shijiazhuang, Hebei

- +86-311-888-33011

- ERW Tube Mills

-

Round, Square, Rectangular Tube

- (Direct Forming to Square) ERW Tube Mills

- Slitting Line

- Cut To Length Line

- Single Unit in Tube Mill

- TIG Tube Mills

- JCOE Pipe production line

Products

- CNC Workshop

- About Us

Quick Link